Our technology is the best option for your process, combining safety and shelf life optimization for perishable products while enhancing biosecurity for your staff and customers.

Oxyion Technology reinforces food safety and quality plans, neutralizing pathogenic bacteria (Listeria, Salmonella, Escherichia coli, etc.), viruses, and decay microorganisms such as molds (Botrytis, Aspergillus, etc.) by up to 99.9% efficiency.

USDA National Organic Standards compliant

FSMA Preventive Control compliant

Continuous 24/7 sanitization

Suitable for use in regular or modified atmosphere settings

Less waste, safer food, and processing environments!

Preventive bacterial control that works!

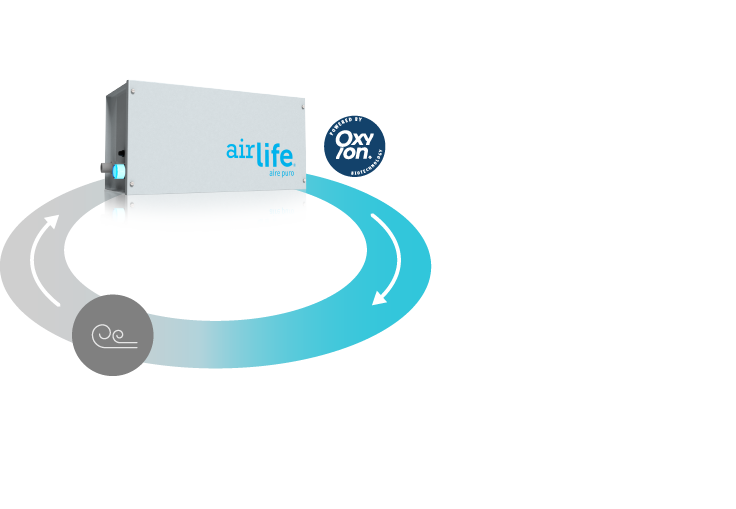

Oxyion limits the exposure to market recalls by strategically implementing sanitization systems in critical areas to protect people and processes. Our process operates 24 hours a day, 7 days a week, in conjunction with the air handling systems to provide consistent sanitization of treated spaces.

Chemical-free protection for people and processes

We protect work areas with our state-of-the-art technology, which provides air disinfection with a chemical-free disinfectant that reaches the treated environment and surface, even in hard-to-reach areas.

Food processing

Fruit and vegetables

Flowers and Plants

Oxyion is a certified state-of-the-art technology that enhances food safety in the handling, storage, and transportation of perishable products. It is an innovative technology that uses air as a vehicle to inactivate contaminating agents

Eliminates 99,9% of bacteria such as Listeria, Salmonella, and E. Coli, etcmo Listeria, Salmonella y E. Coli, etc.

Neutralizes viruses such as Norovirus and H1N1.

Reduces spoilage and prolongs shelf life.

Minimizes ethylene and other harmful contaminants.

Process compatible with FDA and USDA preventive control.

National organic standards approved as a sanitizer/disinfectant

At Airlife we are pioneers in the use of air as a vehicle for continuous sanitization, even during the processing of all types of perishable products.

Benefits

Protection of food and food production environment

Control of unwanted microorganisms or microorganisms specific to the food industry and its processes.

Delayed maturation.

Reduction of dehydration.

Application areas

![]()

Fruit and vegetables

Where to apply Oxyion?

- – Product storage and handling areas

- – Processing and handling rooms

- – Distribution centers

- – Refrigerated transport (trucks and containers)

![]()

Food processing

Where to apply Oxyion?

- – Processing and handling rooms

- – Raw material storage rooms

- – Product preparation, cooking areas, and value-added processing

- – Sorting and packaging areas

![]()

Flowers and Plants

Where to apply Oxyion?

- – Processing and storage areas for plants, flowers and bulbs

- – Controlled greenhouse environments

- – Common areas with exposed products

- – Refrigerated transport (trucks and containers)

![]()

Wine and Beverages

Where to apply Oxyion?

- – Processing and packaging rooms/bottling rooms

- – Holding, processing, and storage of barrels, vats, and containers

- – Sanitization of corks and accessories